The global aircraft parts supply chain is a complex and multi-layered system encompassing manufacturers, distributors, maintenance, repair, and overhaul (MRO) facilities, airlines, and other stakeholders scattered worldwide. The efficiency of this system is critical for the smooth operation of the aviation industry; however, it faces numerous challenges that lead to significant delays, financial losses, and flight safety risks.

One of the primary complexities stems from the heterogeneity of aircraft fleets. Airlines operate various aircraft types, models, and ages, resulting in a vast array of required parts.

Managing the flow of these parts demands sophisticated logistics systems capable of tracking thousands of different items and accounting for the specific characteristics of each component. Data on the global commercial fleet, encompassing thousands of aircraft from various manufacturers and models, is constantly changing.

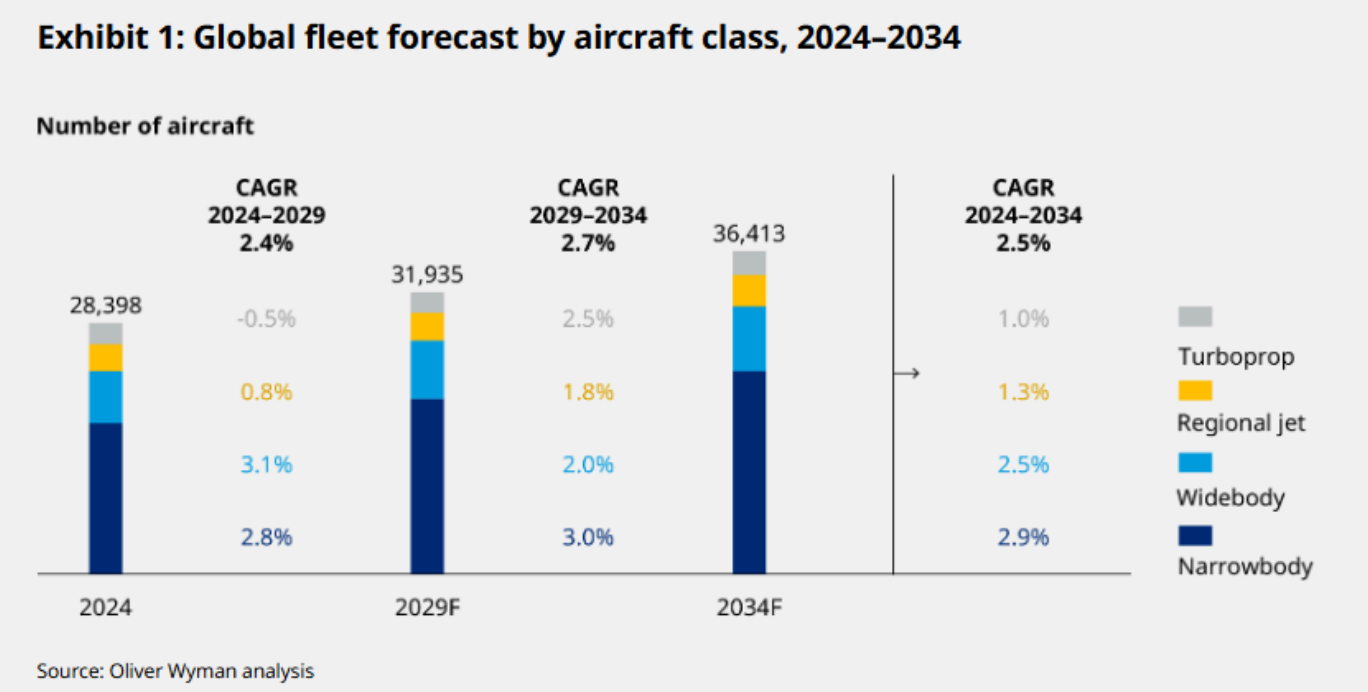

“2024 will be the first year of real growth since the peak reached just before the onset of the COVID-19 pandemic. According to the latest edition of the Global Fleet and MRO Market Forecast 2024-2034, the size of the global fleet will increase 28% over the next 10 years,

expanding from today’s 28,400 aircraft to 36,400 by 2034. The former peak was 27,800.

But COVID has left indelible impressions on the aviation fleet, which will now add aircraft on a slower trajectory than previously predicted. The fleet’s compound annual growth rate (CAGR) over the forecast period will be 2.5% versus the 2.9% projected in last year’s

2023-2033 forecast. The CAGR has been tempered by modest global economic growth — the product of high interest rates worldwide — and lower than anticipated aircraft production.

Where pre-COVID the forecast expected a fleet of more than 39,000 aircraft by 2030, we now do not anticipate reaching that size until 2036 — essentially six years of lost growth for the industry.”

– according to forecasts Oliver Wyman

This diversity creates significant challenges for inventory management and demand forecasting.

Long lead times present another serious problem. Many aircraft parts are made to order and have extended manufacturing and delivery times, potentially causing substantial delays in aircraft maintenance and repair. This situation is exacerbated by the geographical distribution of manufacturers and suppliers, often located across different countries and continents. Delays can arise not only from manufacturing but also from logistical issues such as customs clearance, transportation restrictions, and unforeseen events like pandemics or natural disasters.

Transparency and traceability within the supply chain often leave much to be desired. The lack of a unified system for tracking and managing information about the location and status of parts leads to difficulties in planning, forecasting, and responding to unexpected situations. This is particularly relevant for critical components upon which flight safety depends. The high cost of storing aircraft parts, many of which require specialized storage conditions, is another factor driving up expenses. Inefficient inventory management leads to the accumulation of excess stock, occupying warehouse space and tying up financial resources.

Regulation and certification of aircraft parts represent a complex set of requirements that add further complexity to the supply chain. Ensuring compliance with all regulations and standards requires significant effort and resources.

Addressing these challenges requires a comprehensive approach, including:

Digitization and Automation: Implementing modern IT systems that provide traceability, transparency, and process automation is key to improving efficiency. Inventory management systems (IMS) and enterprise resource planning (ERP) systems enable real-time inventory optimization, demand forecasting, and supply chain management. In this context, Sprocure LLC offers its proprietary IT solution, Pantheon Pro, which automates the procurement process, creates a transparent and resilient supply chain, and performs demand forecasting based on big data analytics. Pantheon Pro significantly reduces manual effort for clients by automating the entire cycle – from search to order, shipment tracking, and invoicing.

Logistics Route Optimization: Utilizing advanced logistics technologies and optimizing

delivery routes reduces the time and cost of parts delivery. Sprocure LLC offers door-to-door delivery services, ensuring parts are delivered directly to the customer.

Risk Management: Developing and implementing risk management strategies to minimize the impact of unforeseen events on the supply chain is crucial. This includes diversifying supply sources, establishing buffer stocks, and developing contingency plans.

Collaboration and Integration: Effective communication and collaboration among all supply chain stakeholders, from manufacturers to airlines, are essential for success. Sprocure LLC works with leading suppliers, fleet operators, MROs, and logistics providers, fostering a robust and efficient ecosystem.

Predictive Analytics: Applying predictive analytics using big data allows for more accurate forecasting of parts demand and optimized inventory management, avoiding shortages and overstocking. Pantheon Pro utilizes these methods, providing accurate, data-driven forecasts.

Optimizing the aircraft parts supply chain is a complex but achievable goal. Implementing advanced technologies, effective risk management, and close collaboration among supply chain participants contribute to increased efficiency, reduced costs, and seamless operation of the aviation industry. Companies like Sprocure LLC, offering comprehensive solutions encompassing process automation, logistics optimization, and predictive forecasting, play a key role in transforming this sector, improving service quality, mitigating risks, and enhancing operational efficiency. This is particularly critical given the continued growth of the global

aircraft fleet and the increasingly complex international economic landscape